1 / 4

1 / 4Rotary axis for AGVs and AMRs

Cena strojne opreme:

Max. torque

50

Nm

24V

Rated speed

6

1/min

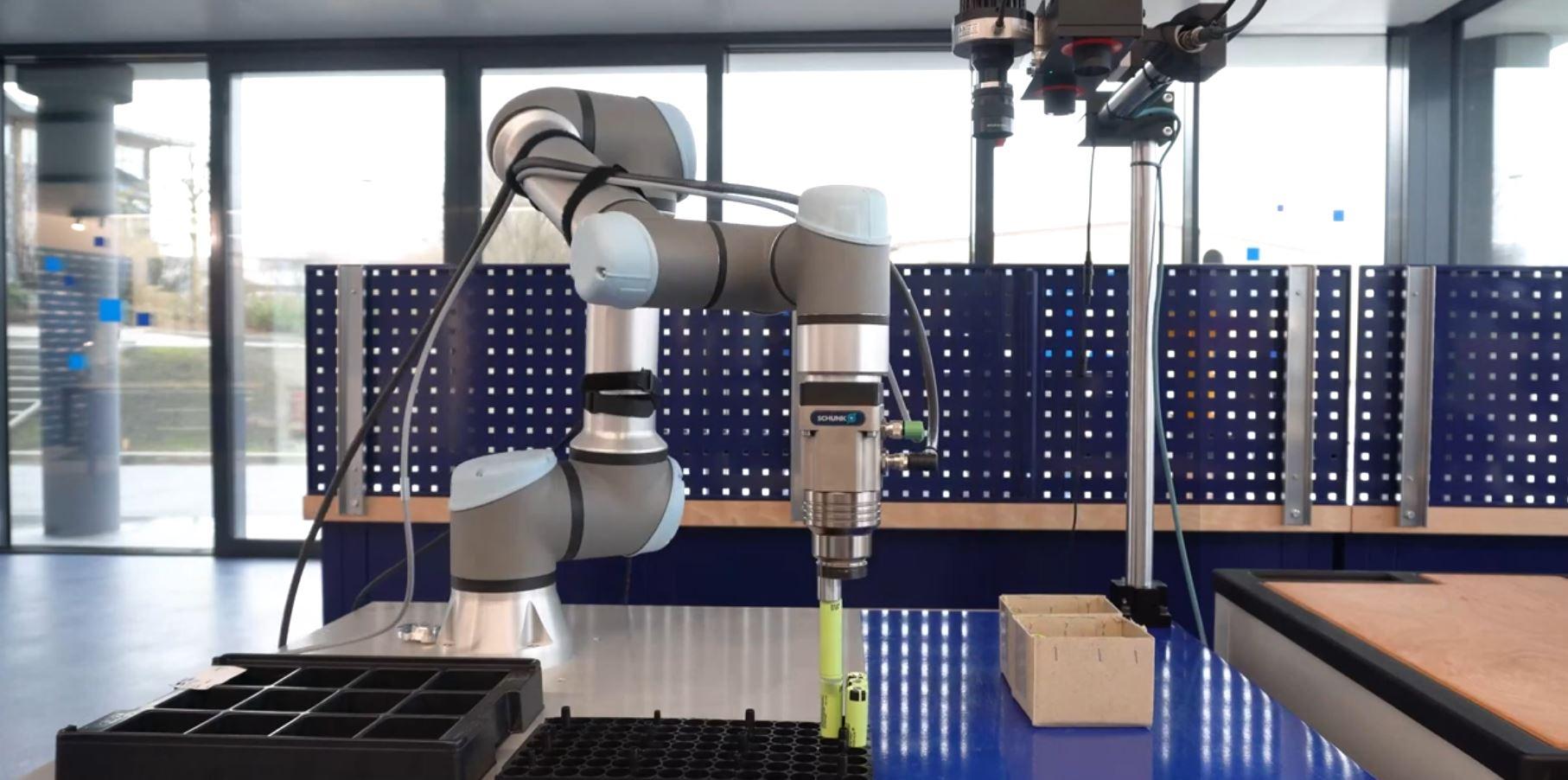

Exploring Driverless Transport Systems with igus robolink® D Rotary Axis

This project focused on researching driverless transport systems (DTS) and their applications, examining both standard operation with a rotary axis and cooperative journeys, where multiple DTS units collaborate for efficient workflows. The integration of the robolink® D external rotary axis from igus enabled precise motion control, making it possible to test and implement these advanced transport scenarios. The flexibility and reliability of the robolink® D system provided the ideal foundation for exploring the potential of DTS in dynamic industrial environments.

What is the Application?

The project enables autonomous transport systems to perform material handling and logistics tasks, supporting both solo and cooperative operations in manufacturing, warehousing, and logistics.

What are the Advantages of the Solution?

Reliable Motion: robolink® D ensures smooth and precise rotary operations.

Collaborative Efficiency: Enables synchronized DTS workflows for multi-unit tasks.

Scalable Design: Adaptable for larger transport networks and more complex scenarios.

What are the Advantages of the Rotary Axis?

The robolink® D rotary axis delivers:

High Precision: Optimized for demanding transport tasks.

Flexible Integration: Easily fits into varying DTS configurations.

Durability: Provides reliable performance over continuous operation.

Innovating Logistics with Driverless Transport Systems

The integration of the robolink® D rotary axis successfully demonstrated the potential of driverless transport systems in modern logistics and manufacturing workflows. By enabling precise and cooperative transport, this setup promises scalable, efficient, and versatile automation for industries seeking to enhance their material handling capabilities.

1 Komponenta